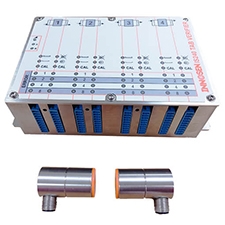

Flat Belt End Conveyor Sensors

9-360-51SS / 11R-360-51SS

DETECT ALUMINUM AND STEEL ENDS WHILE BEING CONVEYED ON A FLAT BELT CONVEYOR

Primarily for die protection in high speed press conveyor systems.

With a fast response time of less than 1 millisecond, the primary use for these sensors is for die protection in high speed press conveyor systems. They can also be used for part tracking, inspection system triggering and jam detection.

Related Products: IS240 Tab Verifier, 11-391-66 End Counting Sensor, End Gap Control System

BENEFITS & FEATURES

Positive End Detection

Special circuitry and tuning enables the end to be detected but not the steel bed beneath the conveyor belt. A specially tailored narrow sensing field also reduces the effect of side metal.

Robust Design

Slim ‘pancake’ style housing and rugged stainless steel construction give these sensors a long life and great reliability.

Maintenance Free

The use of inductive sensing technology eliminates the need for maintenance.

Additional Benefits

The 9-360-51SS and 11R-360-51SS sensors can also be used for part tracking, inspection system triggering and jam detection.

Related Products

TAB VERIFIER

Detects double shells and missing tabs…

End Counting Sensor

Achieve reliable and highly accurate product counts…

End Gap Control System

Maintains the optimum gap at end downstackers…

OFFICES

Spain

Romà Piera i Arcal, 8

08330 Premià de Mar (Barcelona)

Spain

Main Multilanguage Tel:

+34 937 549 526

Email: [email protected]

Hong Kong

11th Floor Dah Sing Life Building

99 Des Voeux Road Central

Hong Kong

Tel: +852 2127 0699

Philippines

808 Citystate Centre Building

709 Shaw Boulevard

1600 Pasig City

Philippines

Tel: +63 2 8696 6965 /

+63 2 8696 6978

USA

7691 N.Overland Trail

80524 Fort Collins

Colorado

USA

Tel: +1 970 305 8721