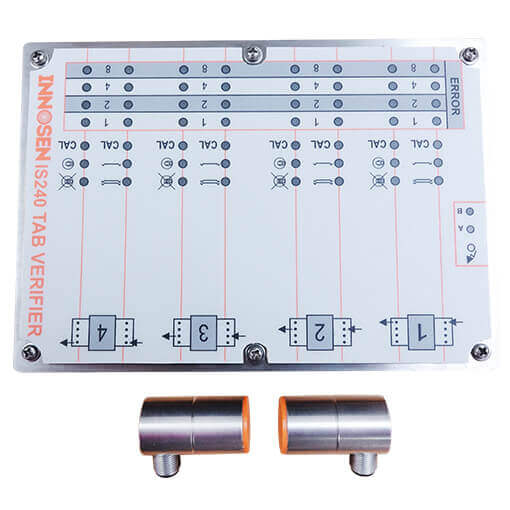

TAB VERIFIER

IS240

DETECTS DOUBLE SHELLS AND MISSING TAB

For each lane, 1 sensor pair is installed at the infeed of the press and other at the outfeed of the press.

Meanwhile, the controller box with key cards inside, comes with multicolored signaling system for easy reading.

Hover to see other images.

BENEFITS

✅ Easier tracking of production faults

✅ Prevent from damaging tooling due to missing shells

✅ Avoid downtime

Specifications | |

|---|---|

| System Components: | Controller, key cards, sensors, and cables |

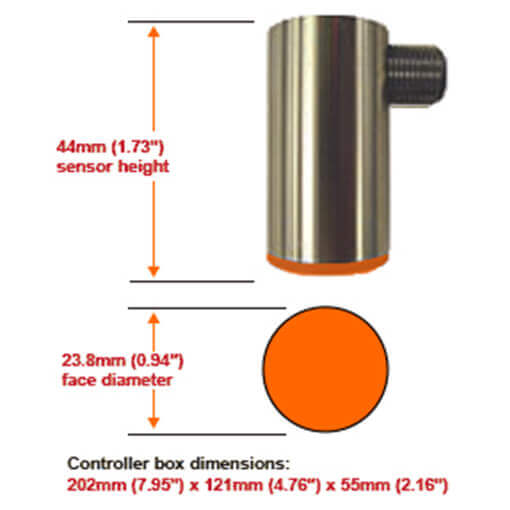

| Dimension: | Controller: 20.2cm (7.95”) x 12.1cm (4.76”) x 5.5cm (2.16”) | Sensors: 4.4cm (1.73”) x 2.38cm (0.94”) |

| Measurement Range: | 0.01 to 0.03cm (0.004” – 0.012”) |

| Response Time: | 2 milliseconds or better |

| Operation Speed: | Up to 1000 strokes per minute |

| Calibration: | Automatic |

| Installation: | Mounted at the infeed and outfeed of the conversion press |

| Environmental protection rating: | IP67 (sensors) IP20 (controller) |

OFFICES

Spain

Romà Piera i Arcal, 8

08330 Premià de Mar (Barcelona)

Spain

Main Multilanguage Tel:

+34 937 549 526

Email: [email protected]

Hong Kong

11th Floor Dah Sing Life Building

99 Des Voeux Road Central

Hong Kong

Tel: +852 2127 0699

Philippines

808 Citystate Centre Building

709 Shaw Boulevard

1600 Pasig City

Philippines

Tel: +63 2 8696 6965 /

+63 2 8696 6978

USA

7691 N.Overland Trail

80524 Fort Collins

Colorado

USA

Tel: +1 970 305 8721