Designed with Canmakers

for Canmakers

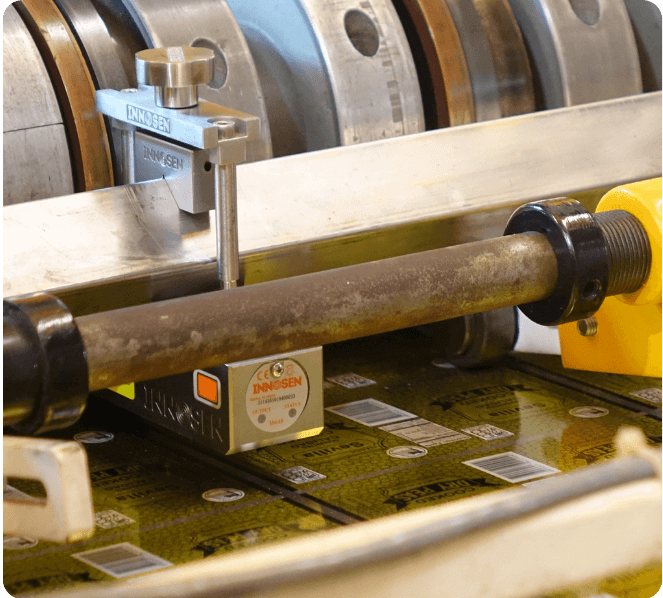

Innosen specializes in developing and manufacturing advanced sensors and quality assurance systems tailored for the metal packaging industry.

Trusted by canmakers in more than 70+ countries.

WHO IS INNOSEN?

Innovative Sensors for Canmaking

Innosen develops and manufactures sensors and quality assurance systems for the metal packaging industry. Everyday, Innosen equips canmakers around the world with reliable equipment to minimize downtime and maximize production efficiency.

“Production does not mean just making loads of cans. They need to be cans that your customers are willing to accept – Willing to pay for.”

SERVICES

Where can we help?

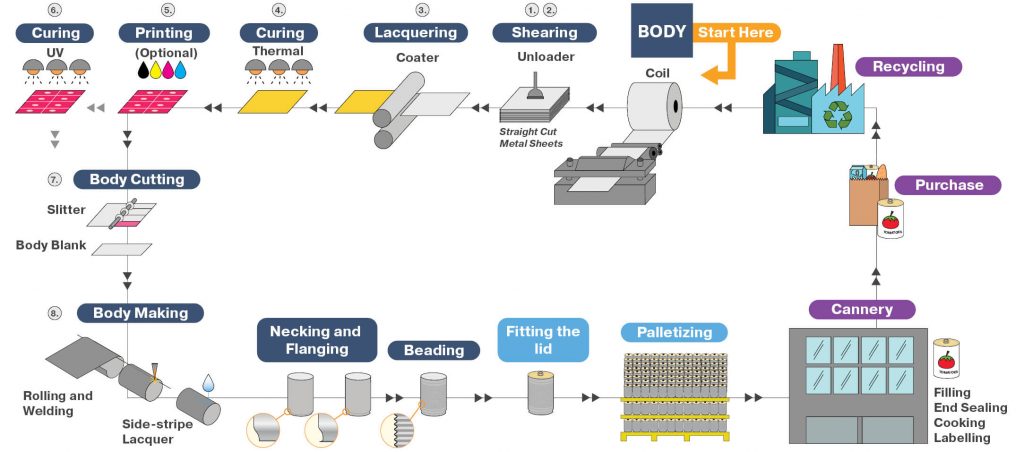

Metal Preparation

Metal preparation process from proper coil cutting, sheet length and lacquer thickness measurement to proper coil lacquering and printing.

Metal Forming

For your metal forming needs, whether it’s for 3-piece welded cans, aerosols, closures and corks or ends.

Quality Assurance

Line Controls

Sensors to improve can-manufacturing efficiency, line speed, and transitions.

Download for free

White Paper

Mastering Coating Control in Metal Packaging by Luc Nelen

Check out the latest whitepaper on coating control.

BLOGS

Latest Articles

How to Maximize Your Coating Line Speed

The IS416 system provides a simplified, data-driven method for maximizing line speed and reducing risks.

2025 Innosen Newsletter Magazine

What happened in 2025? Check our highlights HERE –>

Innosen develops coating gauge to test narrow diameter of aerosol cans

Innosen has unveiled a new internal coating testing device for small-diameter cans.

THE BEST OF INNOSEN

Top-Selling Products

Sheet Skew Measurement System IS416 →

Double Sheet Detector IS231 →

Plain Margin Inspector IS610 →

Get the latest updates today!

Our team is always working on something big. And we want you to be the FIRST to know.

We respect your privacy and we take it seriously. See our Privacy Policy.

Organizations

The IMDPA

Member since 2018.

Dutch Chamber of Commerce

Member.

OFFICES

Spain

Romà Piera i Arcal, 8

08330 Premià de Mar (Barcelona)

Spain

Main Multilanguage Tel:

+34 937 549 526

Email: [email protected]

Hong Kong

11th Floor Dah Sing Life Building

99 Des Voeux Road Central

Hong Kong

Tel: +852 2127 0699

Philippines

808 Citystate Centre Building

709 Shaw Boulevard

1600 Pasig City

Philippines

Tel: +63 2 8696 6965 /

+63 2 8696 6978

USA

7691 N.Overland Trail

80524 Fort Collins

Colorado

USA

Tel: +1 970 305 8721