The 5 Things You Need to Know about Sheet Misalignment

by Niña Munoz, Marketing Executive

Published: March 6, 2020

Sheet coating/lacquering is one of the most important processes in canmaking. A lot of horrific defects could happen to your cans if lacquer or coating is applied to the wrong place. Some of the many problems include poor-quality welds, corrosion (due to missing lacquer) and weld wire breakage, which is why proper sheet positioning should always be observed. In order to ensure that sheets entering the coater are positioned correctly, it should be clear as to why sheets misalign and what the possible effects are if it goes undetected.

We have listed 5 of the most frequently asked questions about sheet misalignment to help you eliminate coating problems NOW:

1. Why do sheets misalign?

Sheet misalignment occurs due to a wide range of reasons. Basically, when you run sheets through high-speed moving lines, there is a huge possibility that the sheet’s position will change at one point, causing problems further along the way. Usually, misaligned sheets result in problems in the coating process.

No matter how well you control the process, approximately 1 in every 2000 sheets will skew or misalign badly as it goes through the rollers.

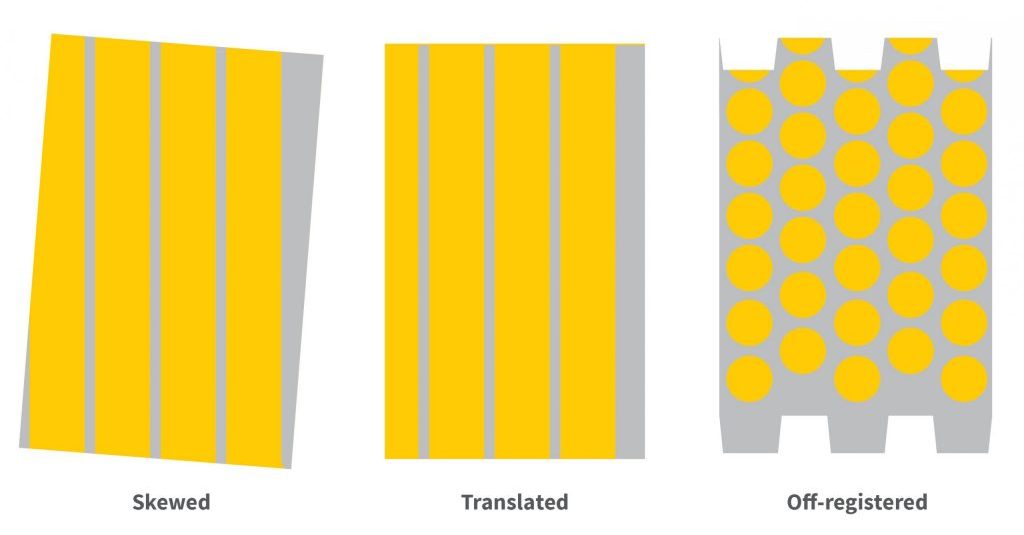

How misaligned sheets look like:

2. What are the kinds of sheet misalignment that can happen?

And where does it occur?

There are several kinds of misalignment of sheets that could happen during the production process. The most common would be what we call skewing or rotation of the sheets. This happens when sheets miss the dogs when entering the rollers.

Sheets can also move sideways. “Translation” occurs in the coater. This happens when sheets miss the side guides when entering the rollers and drift sideways.

Finally, sheets can arrive too early or too late at the coater causing “Registration” issues.

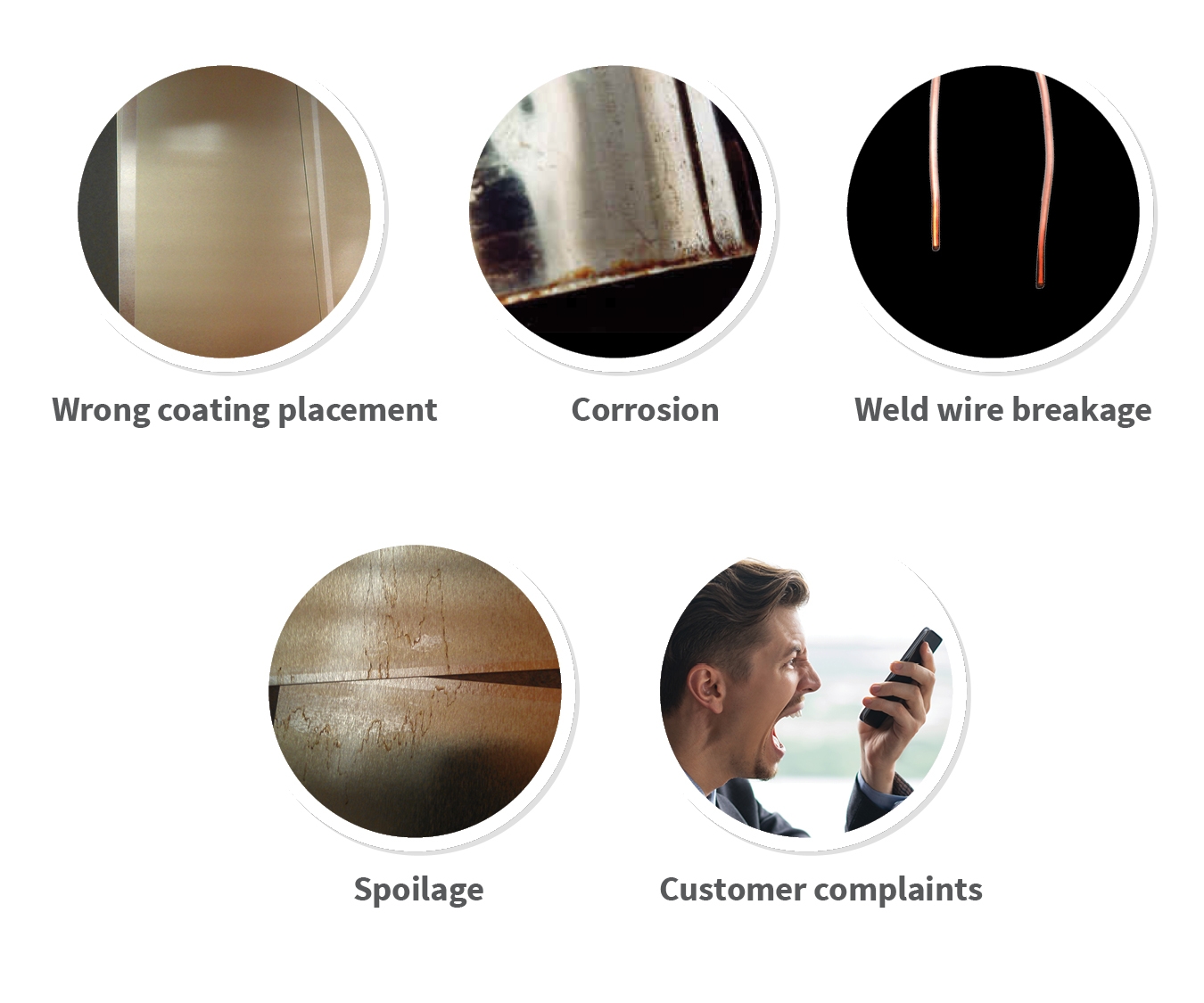

3. What are the problems caused by sheet misalignment?

Misaligned sheets usually cause problems in the coating process. It causes poor coating placement that leads to weld wire breakage, damage to weld rollers or poor quality welds. This further result in spoilage, downtime, and customer complaints due to poor quality products.

Problems that could occur:

4. What can I do to prevent sheets from misaligning?

You will need a device or system that allows you to monitor the accuracy of the alignment of your sheets as they go through the rollers.

The Skew Measurement System is a revolutionary system from Innosen that detects skewed or rotated sheets, giving immediate feedback as the sheets go through the coater.

5. How can I apply maximum process control?

For a complete system for improving the coating process, get the Sheet Translation Measurement add-on module which works with the Skew Measurement System, detecting not only skewed sheets but even “translated” sheets. Get the Sheet Registration Measurement add-on module to protect against poor sheet registration by detecting sheets that arrive too early or too late at the coater.

Learn more about the Sheet Skew Measurement System and other tools to help you with sheet alignment.

IS416 SHEET SKEW MEASUREMENT SYSTEM

Protects against poorly placed coating by detecting skewed (rotated) sheets at the coater.

IS430 MK II SHEET TRANSLATION MEASUREMENT SYSTEM

Adds protection against laterally displaced coating by detecting sheet misalignment at the coater.

IS450 SHEET REGISTRATION DETECTOR

Adds protection against poor sheet registration by warning of sheet misfeeds at the coater.

OFFICES

Spain

Romà Piera i Arcal, 8

08330 Premià de Mar (Barcelona)

Spain

Main Multilanguage Tel:

+34 937 549 526

Email: [email protected]

Hong Kong

11th Floor Dah Sing Life Building

99 Des Voeux Road Central

Hong Kong

Tel: +852 2127 0699

Philippines

808 Citystate Centre Building

709 Shaw Boulevard

1600 Pasig City

Philippines

Tel: +63 2 8696 6965 /

+63 2 8696 6978

USA

7691 N.Overland Trail

80524 Fort Collins

Colorado

USA

Tel: +1 970 305 8721