Area mass sensors

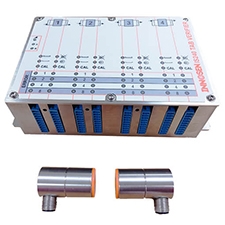

AMS300 / 600 / 2400

UNIQUE SENSORS WHICH HAVE REVOLUTIONIZED MASS CONVEYOR CONTROL ON CANMAKING LINES

Related Products: IS240 Tab Verifier, 11-391-66 End Counting Sensor, End Gap Control System

BENEFITS & FEATURES

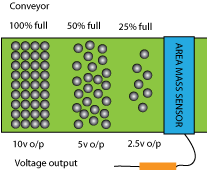

Stable Conveyor Conditions

Conveyor stability is vital for today’s lightweight cans and high speed machinery. The AMS enables complete control, creating optimum conveyor conditions and accumulation space as well as minimum can pressure.

AMS2400 for can lines

AMS2400 for can lines

Cupping Press Modulation

Conveyor Pressure Control

This is accomplished by varying conveyor speed relative to fill level. When full, the conveyor should run at machine rate, creating no excess can pressure. However, as the conveyor empties, the speed should increase. Thus, when recovering from an empty-out situation, conveyor speed is at a maximum, reducing transit and refill times and adding precious seconds into line efficiency.

Related Products

TAB VERIFIER

Detects double shells and missing tabs…

End Counting Sensor

Achieve reliable and highly accurate product counts…

End Gap Control System

Maintains the optimum gap at end downstackers…

OFFICES

Spain

Romà Piera i Arcal, 8

08330 Premià de Mar (Barcelona)

Spain

Main Multilanguage Tel:

+34 937 549 526

Email: [email protected]

Hong Kong

11th Floor Dah Sing Life Building

99 Des Voeux Road Central

Hong Kong

Tel: +852 2127 0699

Philippines

808 Citystate Centre Building

709 Shaw Boulevard

1600 Pasig City

Philippines

Tel: +63 2 8696 6965 /

+63 2 8696 6978

USA

7691 N.Overland Trail

80524 Fort Collins

Colorado

USA

Tel: +1 970 305 8721