WHO ARE THESE MISBEHAVING SHEETS AND HOW TO CATCH THEM?

Written by: Niña Muñoz

Date: May 18, 2020

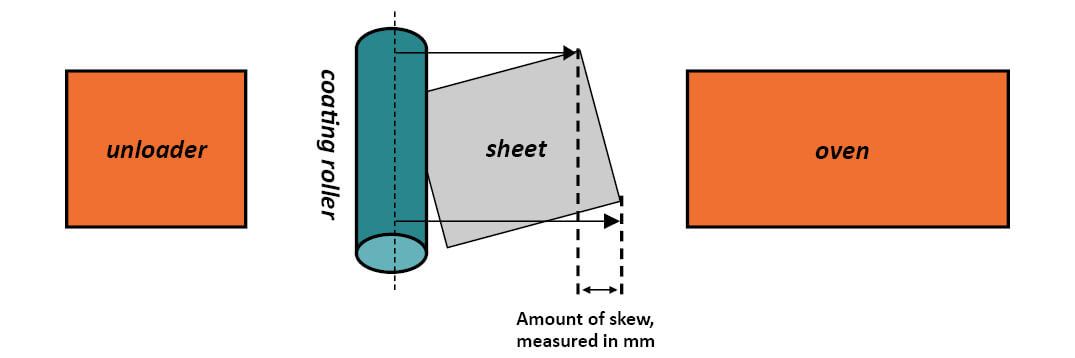

In every 2,000 sheets, 1 will skew, move sideways or register earlier or later as it goes through the coater.

It seems that no matter how well a process is controlled, these problems still occur and will cause issues down the production line and even the value chain. With our can maker friends, we were able to investigate the reasons why these issues happen, here’s my report:

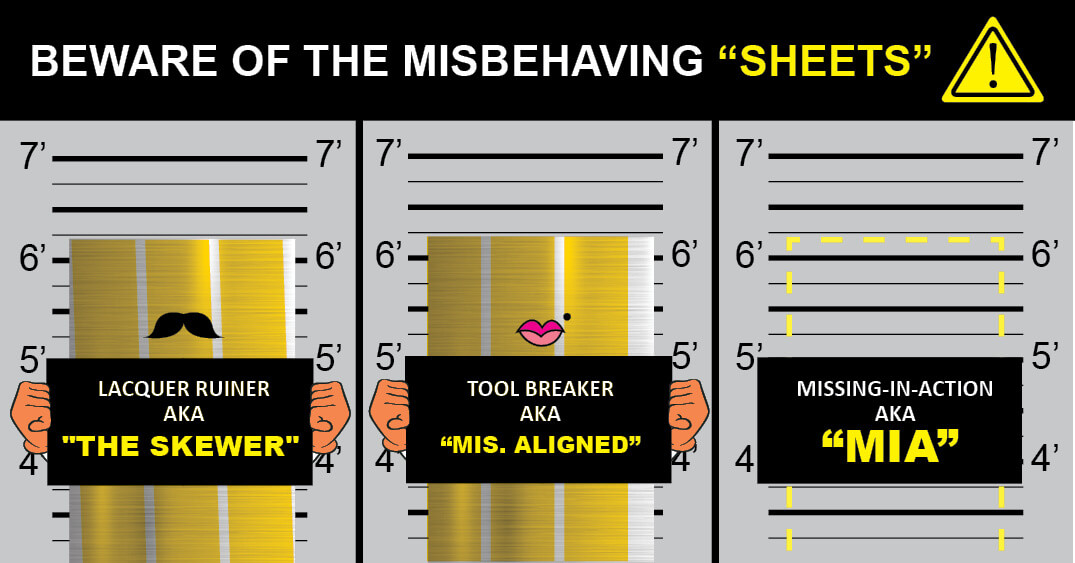

THE SUSPECTS:

Lacquer Ruiner or “The Skewer”

“The Skewer” – He’s so fast, you’ll never know he’s there!

He ruins the production line because he has totally misplaced margins caused by his sudden change of movements.

You know when a sheet goes through a coating or printing press and the leading (or trailing) edge of it should be at a 90-degree angle with the axis of the line? The Skewer always rotates and hates to be at 90 degrees. He does this to screw your entire production and increase your sheet spoilage. Beware of him as he is not easily detected and could form during the last minute of its entrance to the coater.

The Tool Breaker or “Mis.aligned”

“Mis.aligned” – She doesn’t mean to move sideways but she can’t help it!

She’ll blunt your tooling once you let her pass your production. She loves to miss the side guides when entering the rollers, which makes her drift sideways.

She increases the chances of breaking your weld wires because her weld margins are not properly aligned! If she succeeds without getting caught, she will cause your cans to leak and damage your tooling!

Missing-in-action or “MIA”

“MIA” – He doesn’t have a sense of time!

Spot coats and lacquer rolls should always be in sync during the coating process. MIA is either late or early, he doesn’t care about the lacquer roll and when he finally decides to arrive, he causes drama! If left undetected, you’ll end up with lots of spoilage for sure!

THE BULLSHEET SLAYERS:

The best guardians of quality this industry has ever seen

For a complete system to detect these three misbehaving sheets, use the IS415 Sheet Skew Measurement or The SKEWminator, to exterminate The Skewer no matter where or how fast he is. It provides a complete set of data to better analyze and improve the can maker’s process capability.

An add-on to the SKEWminator is the IS430 Sheet Translation Measurement or Misaligned Assassin – it kills Mis.aligned on the spot.

To complete the trinity is the PROMPTpetrator, the IS450 Sheet Registration Measurement– it makes sure that all sheets are in perfect timing as they enter the coater!

“I have had experience with this system now for many years and still believe it to be the best solution available for skew and position measurement.”

RELATED PRODUCTS:

OFFICES

Spain

Romà Piera i Arcal, 8

08330 Premià de Mar (Barcelona)

Spain

Main Multilanguage Tel:

+34 937 549 526

Email: [email protected]

Hong Kong

11th Floor Dah Sing Life Building

99 Des Voeux Road Central

Hong Kong

Tel: +852 2127 0699

Philippines

808 Citystate Centre Building

709 Shaw Boulevard

1600 Pasig City

Philippines

Tel: +63 2 8696 6965 /

+63 2 8696 6978

USA

7691 N.Overland Trail

80524 Fort Collins

Colorado

USA

Tel: +1 970 305 8721