Linear Mass Sensors

LMS2400-XX-UC

Smooth, precise, self-correcting speed control right down the line

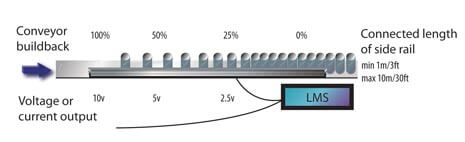

By providing an analog signal that is proportional to can back-up on the conveyor, the LMS can be used to modulate machine or conveyor speed accordingly.

Benefits

- Can density can be monitored at any point on the line

- Machine speeds can be smoothly modulated and coordinated

- Optimum line efficiency

Perfect Speed Matching

When used on the infeed to machines, the LMS controls machine speed to perfectly match the rate of cans being supplied to the machine. It will do this smoothly without overshoot across a wide speed range, eliminating the constant speed variations that are a design feature of traditional, slow-medium-high speed control systems.

Stable Conveyor Conditions

Stable conveyor conditions are vital for today’s lightweight cans and high speed machinery. The LMS enables complete speed control with minimum changes in conveyor back up, so creating optimum conveyor conditions, empty out space, accumulation space and minimum can pressure.

Close Coupled Synchronization

The output of the LMS responds to each and every can instantaneously, which means that a machine does not have to wait for a sensor to cover it before it begins to respond. So close coupled installation of waxers, neckers and testers is possible, with each machine maintaining perfect intermachine back-ups/feed rates.

Conveyor Pressure Control

The LMS enables conveyor speed to be varied relative to back up. When full, the conveyor should run at machine rate, creating no excess can pressure, but as it empties the speed should increase. So when recovering from an empty-out situation, conveyor speed is maximum, thus reducing transit and refill times, adding precious seconds to the line efficiency.

Easy Installation, Even On Complex Conveyors

Another possibility is to isolate and use the side rail on one or both sides of the track to monitor can density instead of using the sensor wire. This makes installation practical on complex conveyor shapes such as swan necks or curved ‘tunnel’ track.

Offices

Spain

Romà Piera i Arcal, 8

08330 Premià de Mar (Barcelona)

Spain

Main Multilanguage Tel:

+34 937 549 526

Alternative Direct Tel:

Français: +33 1 76 64 12 87

English: +44 1905 887845

Fax: +34 937 549 687

Hong Kong

11th Floor Dah Sing Life Building

99 Des Voeux Road Central

Hong Kong

Tel: +852 2127 0699

Philippines

808 Citystate Centre Building

709 Shaw Boulevard

1600 Pasig City

Philippines

Tel: +63 2 696 6965

Fax: +63 2 696 6159