(Updated) Missing Lacquer Problems: How to Detect Them

by Niña Munoz, Marketing Executive

Updated: July 2023

If sheets or cans with missing lacquer get through the production undetected, they can cause serious problems: either can corrosion or blunting of the tooling. These can lead to unplanned downtime, spoilage and customer complaints — all of which represent unnecessary costs.

To reduce the risks of these defects, detecting them at line speed should be a priority. Knowing the causes of sheets with missing lacquer is the first step to stop producing them. Below are the most common causes why you keep on seeing a sheet with missing lacquer in your production:

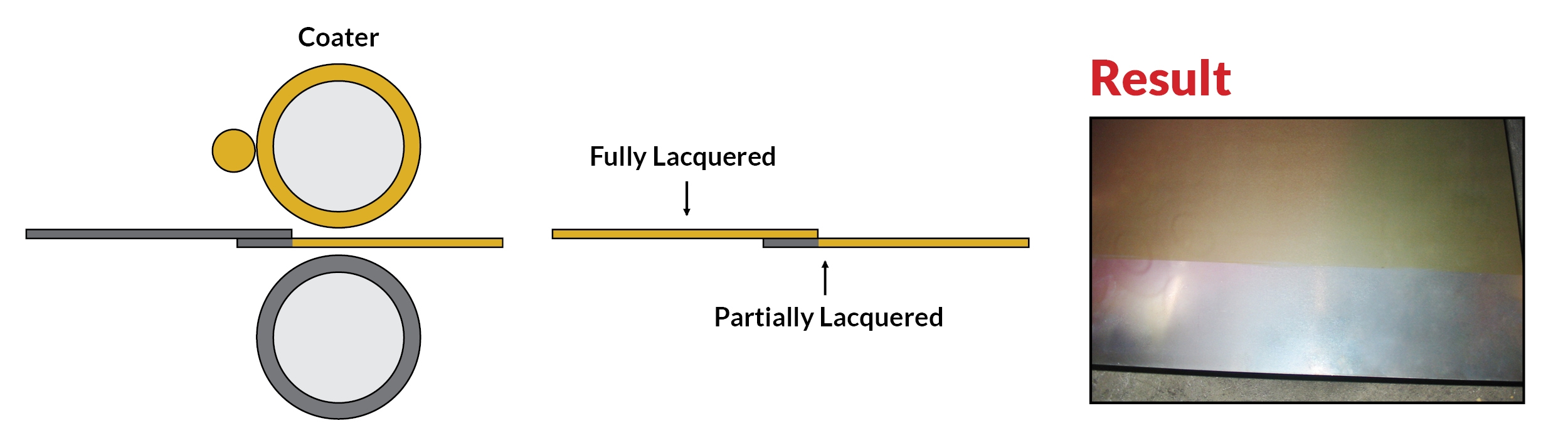

1. Missing lacquer due to partially overlapped sheets that entered the coater

This type of missing lacquer defect is caused by an overlapping sheet that entered the coater, resulting in only one sheet being fully lacquered.

SOLUTION:

If you keep seeing a sheet like this in your production, you would only need to install one IS641-51 Missing Lacquer Detector. This sensor will immediately send a reject signal if it detects a partially overlapped sheet, preventing the sheet to damage your machines due to missing lacquer. This type of missing lacquer defect is caused by an overlapping sheet that entered the coater, resulting in only one sheet being fully lacquered.

Please contact Innosen for a more detailed explanation on the sensor’s detection range.

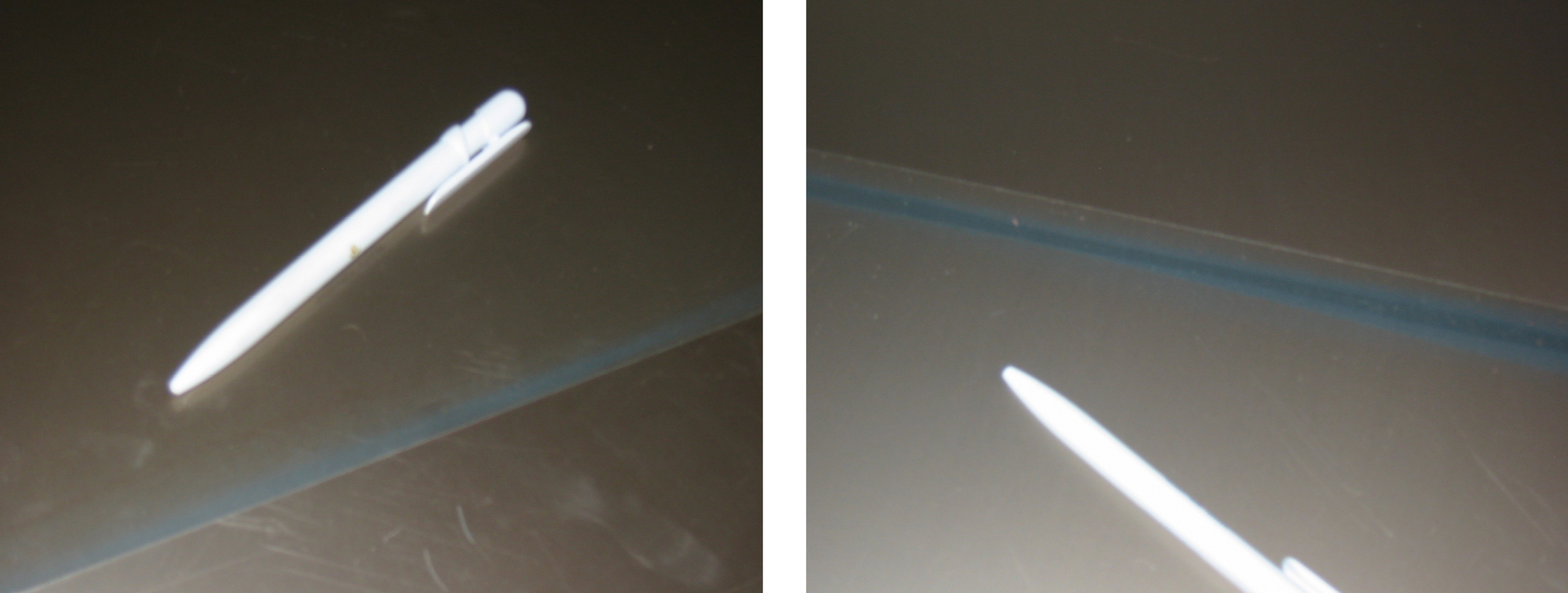

2. Missing lacquer due to lacquer starvation

This means that the lacquer tank did not get filled up on time. There will be missing lacquer on the edges of the sheets for this type of problem. However, you would not know if the missing lacquer will manifest in the left or right side.

SOLUTION:

For this type of defect, you would need two missing lacquer detectors: One to guard the left side of the sheet and one to guard the right side.

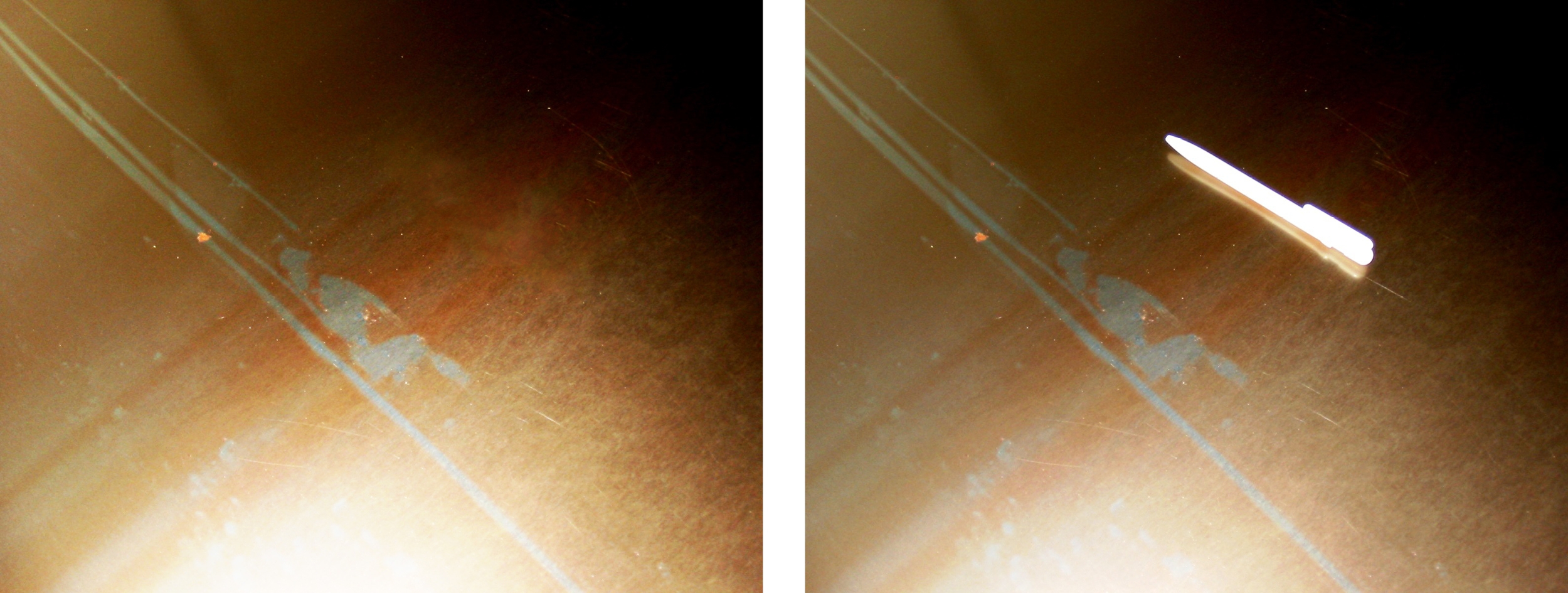

3. Missing lacquer due to contaminated lacquering machine

This is the least frequent cause of missing lacquer on sheets. It is caused by either a label or a rag that has gone through the lacquering machine. A label can usually make one bad sheet. A rag, however, can indent the lacquering roll which may cause more bad sheets with missing lacquer. When this happens, be prepared to double or even triple your costs because it would lead to expensive downtime and horrific sheet spoilage.

SOLUTION:

For this type of problem, it is safe to say that the defect would be about 20cm wide. For over 1200 mm, you would need to install 6 missing lacquer detectors to prevent this problem from happening.

Please contact Innosen for a more detailed explanation on the sensor’s detection range.

WHAT WE RECOMMEND:

IS651 Missing Lacquer Detector

By having only ONE SENSOR, you can:

+ Detect 100% of the overlapped sheets

+ Detect defects caused by lacquer starvation

+ Detect some of the defects caused by contamination

OFFICES

Spain

Romà Piera i Arcal, 8

08330 Premià de Mar (Barcelona)

Spain

Main Multilanguage Tel:

+34 937 549 526

Email: [email protected]

Hong Kong

11th Floor Dah Sing Life Building

99 Des Voeux Road Central

Hong Kong

Tel: +852 2127 0699

Philippines

808 Citystate Centre Building

709 Shaw Boulevard

1600 Pasig City

Philippines

Tel: +63 2 8696 6965 /

+63 2 8696 6978

USA

7691 N.Overland Trail

80524 Fort Collins

Colorado

USA

Tel: +1 970 305 8721