MIXED LABEL INSPECTION

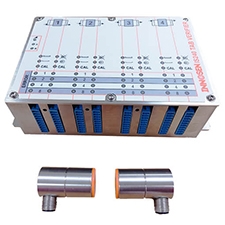

LVC180 LABEL VERIFIER

DETECTS AND REJECTS CANS WITH INCORRECT LABELS ON DECORATED CAN LINES

Label Verifier (LVC180) is a mixed label inspector designed to detect and reject rogue cans with incorrect or mixed labels on 2-piece (DWI) beverage can lines. This high performance, low cost vision system can also act as an entry level deco-inspector. Its compact design and small footprint make it easy to install with minimal disruption to the line.

Related Products: IS240 Tab Verifier, 11-391-66 End Counting Sensor, End Gap Control System

BENEFITS & FEATURES

Minimizes The Risk of Mixed Label HFIs

Label Verifier’s twin sided 85 degree view of the can is much wider than that of comparable systems, ensuring very reliable mixed label detection. This can significantly reduce HFIs, saving time and money and promoting brand protection.

Low False Rejects

The risk of accidental rejects is typically between 1/40,000 to 1/500,000 depending on the sensitivity selected. Spoilage rates are much lower than those caused by less capable systems.

Detects Major Decoration Defects

Label Verifier not only acts as a mixed label inspector but also has the added value of being able to function as an end of line “safety net” for some major deco-defects.

Easy To Learn, Easy To Run

Self-learning technology needs no programming skills and removes the risk of incorrect set-up. Controlled by three push buttons, the system is easy for operators to work with.

High Performance / Low Cost

When it comes to performance and price, the Label Verifier breaks all the rules, allowing rapid payback on your investment.

“Rogue Cans” and HFIs

Incorrectly decorated cans hold up production by creating quarantine situations, often called HFI (Hold-For-Inspection). This can be caused by rogue cans left on the line after a batch changeover or by poorly applied decoration. Detecting and rejecting these cans is vital for reducing HFIs and avoiding customer complaints. Even at speeds of over 3000 cans per minute, this mixed label inspection unit detects rogue cans left over from a previous design run. It may also detect cans with major decoration damage and defects such as “silver bullets” (bright cans). It has even proved successful at spotting color fades, voids, water spots and partial brights. The optional product tracker and rejecter ensures that these defective cans do not reach the customer or cause costly HFIs.

Related Products

TAB VERIFIER

Detects double shells and missing tabs…

End Counting Sensor

Achieve reliable and highly accurate end counts…

End Gap Control System

Maintains optimum end gap with line speed control…

NOS BUREAUX

Spain

Romà Piera i Arcal, 8

08330 Premià de Mar (Barcelona)

Spain

Tél. Principal Multilangue:

+34 937 549 526

E-mail : [email protected]

Hong Kong

11th Floor Dah Sing Life Building

99 Des Voeux Road Central

Hong Kong

Tél : +852 2127 0699

Philippines

808 Citystate Centre Building

709 Shaw Boulevard

1600 Pasig City

Philippines

Tél : +63 2 8696 6965 /

+63 2 8696 6978

USA

7691 N.Overland Trail

80524 Fort Collins

Colorado

USA

Tél : +1 970 305 8721