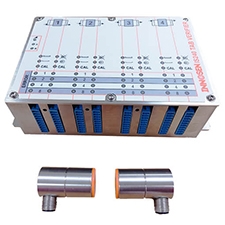

Bagging count system for beverage cans

A4-403

a cost effective system for identifying under or over-filled sleeves of ends

The system consists of two specialized non-contacting End Count Sensors designed for reliable and highly accurate counts to allow precise monitoring with 100% confidence. The sensors are positioned on a carriage mounted to a linear bearing, which allows the stack to be easily and swiftly moved past the counter. Ends are counted in ‘stick’ form, which makes it easy to unload and reload ends into the bag using the guides provided. A simple fixture assembly makes for quick and straightforward installation. Intuitive ‘go/no-go’ status lights are designed for easy operation.

Related Products: IS240 Tab Verifier, 11-391-66 End Counting Sensor, End Gap Control System

BENEFITS & FEATURES

Eliminate Inaccurate Manual Counting

By cutting out costly and inaccurate manual counting and avoiding unreliable hand held counters, Sencon’s A4-403 Bag Count Validator provides fast payback for a relatively low investment.

Reduce Spoilage

Reduce Labor Costs

Simple Set Up

High Performance / Low Cost

By consistently supplying accurately counted bags, you will protect your brand reputation and keep your customers satisfied.

Setting up the Bag Count Validator is simple and quick. Since the unit is portable, it is easily moved from line to line and plugged into a local power source. All an operator need to do is:

- Reset the counters

- Slide the ends onto the rack using the supplied horns.

- Adjust the sensors to the height of the ends

- Start counting

Easy to Use

The ends are easy to load and unload in stick form using the horns provided. Sensors used on the system are specially designed to achieve highly accurate and reliable counts each time. By simply sliding the sensors from right to left over the lids, a highly accurate count is taken. (Typically 99.998% accurate when correctly applied and set up).

Quick, Intelligent and Flexible

The sensors are unidirectional, so the system only counts forward, which means that even if ‘jiggling’ occurs, a correct count is still taken. Two counters on the system provide immediate validation. The sensors are adjustable to allow for different end finishes. If your application involves an unusual size, shape or coating, please contact your local Sencon office.

Related Products

TAB VERIFIER

Detects double shells and missing tabs…

End Counting Sensor

Achieve reliable and highly accurate product counts…

End Gap Control System

Maintains the optimum gap at end downstackers…

NOS BUREAUX

Spain

Romà Piera i Arcal, 8

08330 Premià de Mar (Barcelona)

Spain

Tél. Principal Multilangue:

+34 937 549 526

E-mail : [email protected]

Hong Kong

11th Floor Dah Sing Life Building

99 Des Voeux Road Central

Hong Kong

Tél : +852 2127 0699

Philippines

808 Citystate Centre Building

709 Shaw Boulevard

1600 Pasig City

Philippines

Tél : +63 2 8696 6965 /

+63 2 8696 6978

USA

7691 N.Overland Trail

80524 Fort Collins

Colorado

USA

Tél : +1 970 305 8721