Innosen Launches IS9561 Tube Probe — A New Standard in Coating Thickness Control

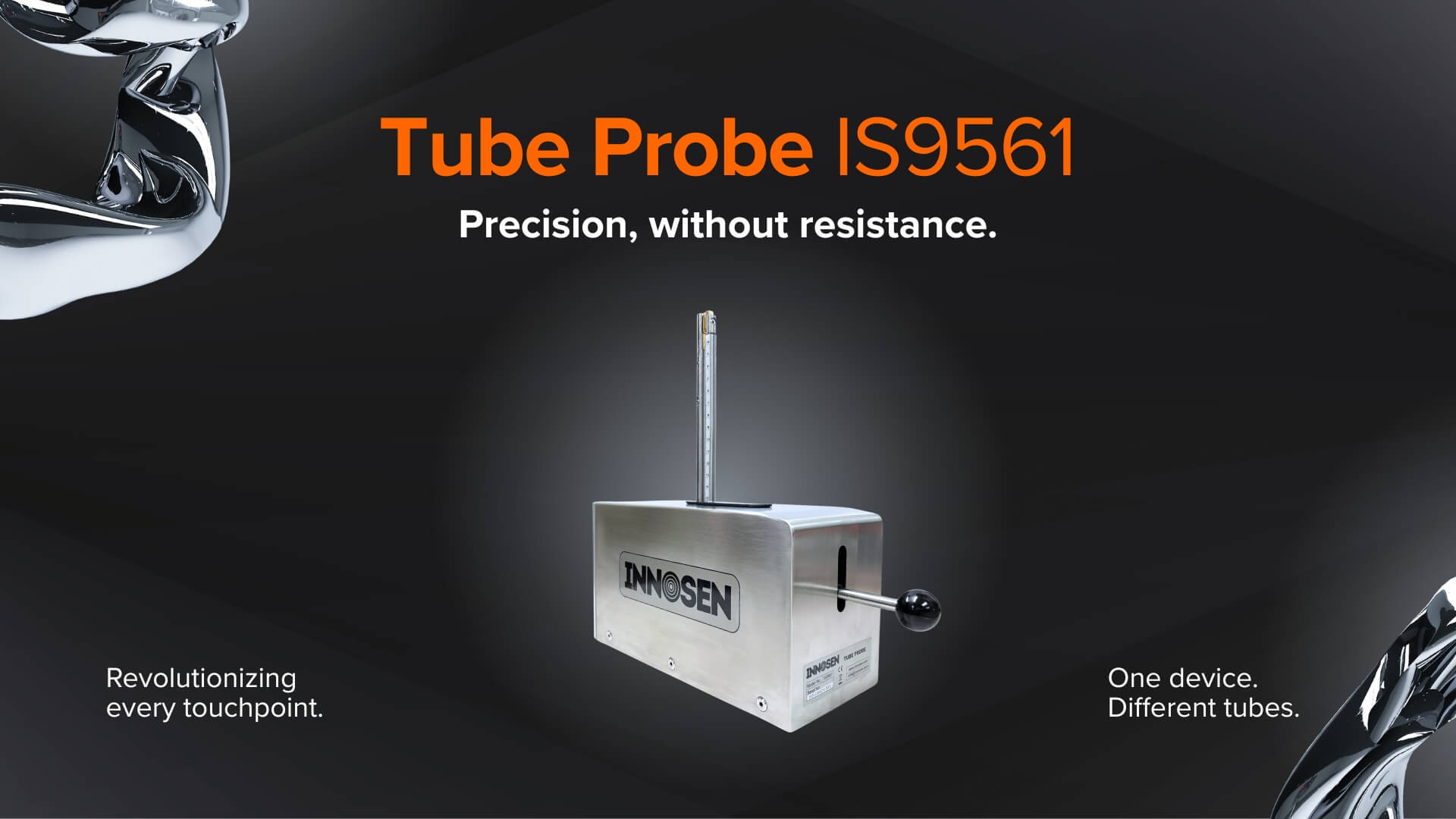

May 2025 — Innosen, a global leader in sensor innovation for the metal packaging industry, proudly introduces the IS9561 Tube Probe, a next-generation lacquer thickness measurement tool engineered for unmatched accuracy, speed, and versatility across all metal tube types.

Crafted for Precision. Built for Simplicity. Designed for Every Tube.

The IS9561 is a capacitive manual probe that measures both interior and exterior coating thickness of metal tubes — delivering zero stiction, low noise, and higher accuracy than traditional methods. It’s ideal for packaging applications across cosmetics, pharmaceuticals, industrial products, and more.

With its universal compatibility, flexible design, and optimal load handling mechanism, the IS9561 resolves the limitations of single-purpose tools, enabling manufacturers to measure tubes of various diameters — including those as small as ⌀12 mm — all with one compact, easy-to-use device.

“It’s not just about measurement — it’s about measurable progress,” said Luc Nelen, President at Innosen. “The IS9561 empowers teams to move faster, reduce waste, and trust the numbers — no matter the tube size or shape.”

Defining Features of the IS9561 Tube Probe:

✅ Stiction-Free Accuracy

A rotary flexure system replaces traditional bearings — eliminating friction and measurement noise for ultra-precise lacquer thickness readings.

✅ Lightweight Engineering

Force multiplier flexure construction reduces counterweight needs while maintaining consistent probe pressure — making the probe lighter and easier to use.

✅ Universal Tube Compatibility

Handles a wide range of tube diameters and styles — including tubes, aerosols, and sidestripes — without the need to switch between devices.

✅ Quick Probe Tip Replacement and Deployment

Change probe tips in under a minute using the included extraction tool for minimal downtime and faster throughput.

✅ Dual-Surface Measurement

Measure both the internal and external lacquer layers — whether both sides of the tube are lacquered or just one side —

Lacquered Outer + Sheet + Lacquered Inner or Bare Outer + Sheet + Lacquered Inner.

✅ No Control Boxes or Dials

Operate the probe effortlessly with a simple lever and clip system. No need for complex interfaces — just fast, intuitive operation.

Accuracy. Versatility. Effortless Control.

The IS9561 sets a new benchmark in lacquer thickness control — combining engineering precision with user-friendly design. Its arrival marks a turning point for tube manufacturing quality control: one tool, limitless capability.

Whether you’re a packaging engineer, quality control lead, or plant technician, the IS9561 Tube Probe delivers the confidence, speed, and precision modern production demands.

The future of coating thickness control is here.

Smaller. Smarter. Stronger.

Only from Innosen.

Get to know IS9561 Tube Probe:

Know the Specifications:

Tube Probe IS9561

Measures the internal and external coating thickness on aluminium collapsible tubes.

OFFICES

Spain

Romà Piera i Arcal, 8

08330 Premià de Mar (Barcelona)

Spain

Main Multilanguage Tel:

+34 937 549 526

Email: [email protected]

Hong Kong

11th Floor Dah Sing Life Building

99 Des Voeux Road Central

Hong Kong

Tel: +852 2127 0699

Philippines

808 Citystate Centre Building

709 Shaw Boulevard

1600 Pasig City

Philippines

Tel: +63 2 8696 6965 /

+63 2 8696 6978

USA

7691 N.Overland Trail

80524 Fort Collins

Colorado

USA

Tel: +1 970 305 8721